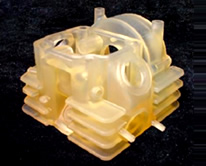

SLA is a rapid prototyping process that creates a model from 3D data using a process known as stereolithography. The machine builds parts one layer at a time using a highly accurate UV laser to solidify one layer of photosensitive resin before progressing to the next. SLA machines apply layer thickness so precisely the tolerance can be controlled to ±0.05mm. Once all layers of the part are complete it is baked in a UV oven to be cured. Our SLA machines utilize the most advanced laser technologies producing parts with high accuracy and an excellent surface finish. The process is extremely accurate and can be used to create very complex models and prototypes it is also a very quick process.

| MaxSize | 450mmx450mmx350mm |

| Tolerance | +/-.005 +.001/mm |

| Precision | +/-0.005mm |

| Equipment |

3d system |

| Material |

Imported SOMOS 120?SOMOS 14120 |

07378265

87321700

99274999

Advantages:

© Copyright Superior Prototype Co., Ltd. All rights reserved.

TEL: +86-755-88213561 FAX: +86-755-81723750 E-Mail: sales@Super-prototype.com